Taste Sweet Success. Bigger, Better Berries!

High Value. High Risk

A key success factor of farming is to minimize risk.

There are many factors you cannot control, but one factor you can control is the irrigation system you choose to install. Strawberry is a high value but extremely sensitive crop. Using a less than ideal drip irrigation system may save a small amount of money, but you add extra risk to your entire cropping system and therefore results. As strawberries are one of the highest revenue crops per square meter, it does not make economic sense to risk significant yield loss to make a small saving during installation. Whether growing in open-field, under tunnel, or using soilless, you can reduce your risk and maximize your success by using the best drip irrigation system.

Are there alternatives to drip?

Technically – yes. Commercially viable – not really.

Furrow (flood) irrigation is not viable for the production of fresh market strawberries. In regards to sprinklers, drip irrigation continually applies the most uniform application of water, which makes a big difference in potential revenues. Additionally, with sprinklers you increase your risk of plant disease and fruit damage due to water being sprayed on the leaves and fruit. Strawberries are very sensitive to disease and growers are under pressure to reduce spraying of chemicals on their crop. Sprinklers are often required at the initial stages of growing, however they should not be used for the majority of the cropping cycle.

Open Field & In Soil Tunnel Application

Growing open field and in soil with tunnels require very similar irrigation techniques

| Considering growing in tunnels? Your environmental conditions and desire to have the ability to grow earlier in the season will define whether you should use tunnels. An advantage of growing in tunnels is that they protect your crops from environmental elements; however in warmer climates, you need to be careful the tunnels do not create too much heat and humidity which can lead to disease, insect problems and fruit rot. |  |

Considering growing in tunnels? Your environmental conditions and desire to have the ability to grow earlier in the season will define whether you should use tunnels. An advantage of growing in tunnels is that they protect your crops from environmental elements; however in warmer climates, you need to be careful the tunnels do not create too much heat and humidity which can lead to disease, insect problems and fruit rot.

First – getting runners off to a flying start

If you grow from runners which are far more economical than seedlings, you should install a supplementary sprinkler irrigation system for the initial growing stage.

Runners have virtually no functioning roots, so you need to keep your leaves turgid while their roots form. Overhead sprinklers are the best solution during this initial stage of growth.

Typical System

- In open field systems, use Rivulis S5000 Plastic Impact Sprinklers

- Spacing: 9 m (down rows) x 10 – 11 m (across rows depending on bed configuration)

- Model: Rivulis S5000 High Angle Single Nozzle sprinklers will deliver high uniformity of crop coverage

- For tunnels, either use Rivulis S5000 Plastic Impact Sprinklers as per above, or use inverted Rondo Sprinklers

- Inverted Rondo sprinklers are chosen based on criteria to ensure adequate coverage of the plants including the height of the sprinkler above the grow bags, the slope of the tunnel roof and the distribution of the grow bags

Helpful Hints

- Operate your sprinklers during planting to minimize strawberry runner stress

- In later crop growth stages, use sprinklers for cooling and to wash dust off plants

Growing your Crop with Rivulis T-Tape

4 reasons why Rivulis T-Tape is your go to drip irrigation product for strawberries:

Minimize Risk

Rivulis T-Tape is a premium drip tape that strawberry growers prefer above all else due to its uniform flow, unique internal design and turbulent flow channel emitter manufactured into the tape itself that delivers clogging resistance, even under poor water quality conditions. Rivulis T-Tape is one of the most popular drip products worldwide and is extremely common in California, Mexico, Spain, Italy and Australia strawberry production.

Use Close Dripper Spacing

Strawberries are typically planted at 25 – 30 cm intervals. Each plant will typically yield between 0.75 – 1.3 kg of fruit. This makes close dripper spacing very important.

In addition to helping with crop uniformity, closer dripper spacing makes it easier to leach accumulated salts both below and to the edge of the bed. Strawberry has a long crop cycle and using close dripper spacing helps prevent accumulated salt build up between drippers by making it easier to push the salts away from the crop. Wider dripper spacing can result in residual salts being left in the root zone between the emitters.

We recommend dripper spacings of 15 – 20 cm (maximum) to provide very uniform fertilizer and water distribution, even with short irrigation times commonly used by strawberry growers. Rivulis T-Tape has an integrated emitter design that allows for easy close dripper spacing, even as low as 10 cm.

| By applying dye through a drip irrigation system and then cutting away the soil, we can observe how water moves through different soils. In more sandy soils, lateral water movement sideways is much lower compared to the movement of water down the soil profile. In these environments, close dripper spacing is critical to ensure all strawberry plants receive adequate water and fertilizer. |  |

By applying dye through a drip irrigation system and then cutting away the soil, we can observe how water moves through different soils. In more sandy soils, lateral water movement sideways is much lower compared to the movement of water down the soil profile. In these environments, close dripper spacing is critical to ensure all strawberry plants receive adequate water and fertilizer.

Rohan Prince. Using dye to show water movement below drip irrigation. Department of Primary Industries and Regional Development. Government of Western Australia. (2016)

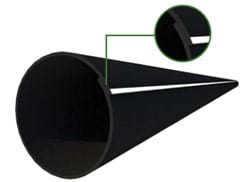

Slit Outlet to Prevent Soil Ingestion

While the tape is installed under plastic mulch, it should also be shallow buried a few centimetres to prevent it from ‘snaking’ under the plastic mulch. A challenge when burying drip lines is soil ingestion at shut off. Rivulis T-Tape was specifically engineered with a slit outlet that closes at shut off to help prevent soil ingestion.

Seam Design for Easy Retrieval

| At the end of the season the plastic mulch and tape is often removed at the same time. Rivulis T-Tape has a seam along the length of the tape that provides an extra layer of strength to help prevent snapping during retrieval. |  |

At the end of the season the plastic mulch and tape is often removed at the same time. Rivulis T-Tape has a seam along the length of the tape that provides an extra layer of strength to help prevent snapping during retrieval.

Typical Rivulis T-Tape System

- Standard bed: 1 – 2 lines of plants per bed.

- 1.2 – 1.4 m between beds

- 0.25 – 0.30 m between plants

- Density 40,000 – 60,000 plants / hectare

- Generally use 1 row of Rivulis T-Tape per bed

- Wide bed:

- 3 – 4 lines of plants per bed

- 1.5 – 1.8 m between beds

- 0.25 – 0.30 m between plants

- Density 40,000 – 60,000 plants / hectare

- use 2 – 3 rows of Rivulis T-Tape per bed

- Rivulis T-Tape:

- 16 – 22 mm depending on run length

- 6 – 12 mil wall thickness depending on insect risk

- 0.5, 0.75 or 1.0 lph dripper and 15 – 20 cm dripper spacing. Dependent on soil, water and hydraulic requirements

Helpful Hints

- The benefit of having wider beds with extra lines of plants should be considered along with the additional difficulty and cost for harvest as wider beds make it more difficult to reach over to pick strawberries and perform other activities

- Do not run your tape or submains up-hill. If you have sloping ground, it is better to run downhill where the friction in the pipe can help balance the increased pressure due to gravity

Soilless / Hydroponic Systems

Why choose a soilless system?

| A common reason is labor saving. Harvesting strawberries is expensive. The harvest season is drawn out and it is time consuming, difficult work. In soilless installations, harvesters can pick while standing which is much more efficient than reaching over multiple rows on the ground. The second reason is it avoids poor soil and soil borne plant pathogens such as Verticillium dahlia and Macrophomina phaseolina. When growing in soil, the soil must be disinfected. Methyl bromine is banned in most countries and finding suitable options to disinfect soils is difficult and expensive. This challenge is effectively removed when growing strawberries using soilless. The third benefit is environmental protection and ability to control the growing climate if combined with protected cropping. |  |

A common reason is labor saving. Harvesting strawberries is expensive. The harvest season is drawn out and it is time consuming, difficult work. In soilless installations, harvesters can pick while standing which is much more efficient than reaching over multiple rows on the ground. The second reason is it avoids poor soil and soil borne plant pathogens such as Verticillium dahlia and Macrophomina phaseolina. When growing in soil, the soil must be disinfected. Methyl bromine is banned in most countries and finding suitable options to disinfect soils is difficult and expensive. This challenge is effectively removed when growing strawberries using soilless. The third benefit is environmental protection and ability to control the growing climate if combined with protected cropping.

Typical System:

- Use Rivulis Supertif PCND drippers

- The world’s most advanced dripper, with pressure compensation, no-drain feature for pulse irrigation, and a self-cleaning mechanism

- 1.1 lph flow-rate and intervals of 15 cm is generally sufficient if using a 1 peg per dripper design in long grow bags that contain multiple plants. In single plant per grow bag systems, 1.2 – 2.2 lph is common

- Use for multiple seasons with amazing reliability

Helpful Hints

- It is best to use 1 dripper with 1 hose and peg instead of 1 dripper to multiple pegs

- This system of 1 dripper distributed to multiple pegs is less recommended because if one dripper fails, damage will be multiplied by the amount of pegs connected to it. The small savings benefit of using fewer drippers does not make it worth the risk.

- One ripper and 1 peg provides the best protection to your crop.

- Similar to in soil tunnel applications, if growing from runners, Rivulis Inverted Rondo should be installed according to specifications of the greenhouse design to assist with the development of the roots of runners.

|

|

Innovation Showcase:

Greenhouse installation with Rivulis D5000 PC

Highlighting a new innovation for growing strawberries.

- Hanging Styrofoam trays (10 cm x 10 cm) are installed

- Rivulis D5000 PC 16 mm, 40 mil wall thickness, 15 cm dripper spacing, and low-flow 0.65 lph is installed to run along the length of the trays.

- Trays are filled with peat and planting at a rate of 9 x strawberry plants per meter.

- The trays hang at a gradual decline so that water can be reclaimed at the end of the rows. The goal is for 35 – 40% of applied water to flow-out to help protect against salinity. This water with remaining nutrients, is applied to other in-soil crops grown on the farm with additional reuse options available with the correct treatment.

|

|

Unique Benefits:

- Lower cost than typical greenhouse systems

- The drip line can be used for multiple seasons

- Much easier to install – no individual one-by-one insertion of drippers and pegs

- No need to worry about workers knocking pegs or damage to the irrigation system

General Tips for a Great Strawberry Harvest

- Strawberries prefer a full wet-up and dry-down irrigation cycle. A common mistake is to over irrigate. In wet conditions, the strawberries uptake more of the highly soluble nutrients only. However, it is only as the soil dries that the strawberries can efficiently take-up insoluble nutrients as well. Water stress is an absolute no for strawberries, so you need to carefully manage the dry-down to not reach a stress point.

- Calcium is important for growing strawberries with good cell strength. Calcium applications should be considered for high quality fruit. Calcium uptake will be most effective when a sufficient wet-up and dry- down irrigation schedule is implemented.

- When planting in soil, managing soil disease and nematodes is critical. This is achieved mainly through disinfection or moving the location of your strawberry production.

- Match the variety to the cropping season and climate. For example, do you want short day, day neutral, or long day flowering? While it can be tempting to plant early to maximize early harvest yields, if you plant too early, you may have reduced yield as the plants undergo a period of dormancy.

- For best dripper spacing, keep dripper spacing under 20 cm, and ideally at 15 cm.

- Rivulis T-Tape is designed for a nominal pressure of 0.55 bar. However for most uniform application in strawberries, it is recommended to run at a slightly higher pressure with approximately 0.85 bar pressure at the start of the tape. This will ensure the best application of water on lightly undulating terrain, even as pressure decreases along the length of the tube. The Rivulis hydraulic design center can help design the best irrigation system to minimize flow variability and to increase uniformity.

- Strawberries are sensitive to salinity. If you have slightly saline water, manage this risk by using close dripper spacing and applying enough water to push the salinity away from the root zone.

- Save fertilizer and improve yield and fruit quality by undertaking regular sap and soil tests during the cropping stages.

Case study outcomes are for information purposes only and actual results may vary. This literature has been compiled for worldwide circulation and the descriptions, photos, and information are for general purpose use only. Please consult with an irrigation specialist and technical specifications for proper use of Rivulis products. Because some products are not available in all regions, please contact your local dealer for details. Rivulis reserves the right to change specifications and the design of all products without notice. Every effort has been used to ensure that product information, including data sheets, schematics, manuals and brochures are correct. However information should be verified before making any decisions based on this information.