Take control of your Corn / Maize Production

Increase Corn / Maize Yield & Reduce Product Costs

You can increase your yield and reduce your cost of production by reducing water stress through:

As the table below shows, permanent yield loss occurs depending on the stage of growth. Water stress during pollination can lead to permanent yield loss of 8.0% per day. In today’s competitive environment, this amount of yield loss can lead to lower production and less profit.

Yield loss per day due to water stress

Source: Rhoads and Bennett (1990) and Shaw (1988)

Choosing the Right Irrigation Method

There are three main options for irrigation of corn Crop: furrow (flood), sprinkler (pivot or lateral move), or drip (on-surface or subsurface). Here we will discover the many unique advantages drip irrigation provides for both increasing your yield and minimizing your inputs.

Maximize Your Land with Drip Irrigation

If you have 1,600 ha of land and you chose to irrigate with center pivots, 21.46% (343 ha) of your land would not be irrigated due to pivots not reaching the corners.

Australia Case Study: The Australian Government’s Scientific Research Agency (CSIRO) conducted a study comparing the yield and net irrigation water productivity of subsurface drip irrigation to lateral move sprinkler irrigation and flood irrigation. The study was held in Murrumidgee, Australia from 2004 – 2006. The results clearly show the benefits of using drip irrigation over other irrigation methods:

- 30% Yield increase Drip vs. Flood Irrigation

- 15% Yield increase Drip vs. Sprinkler Irrigation

- 40% Higher water productivity Drip vs. Flood Irrigation

Financial Benefits of Using Drip Irrigation Over Pivots

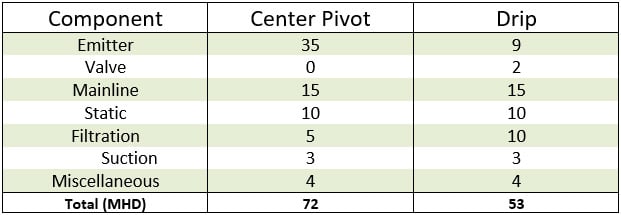

The table below shows the total pressure required to operate a center pivot compared to a drip irrigation system calculated by each component of the total irrigation system

Portugal Case Study: Pivot vs. Surface Drip

Fundação Eugénio de Almeida | Évora in Sao Maço District, Alentejo, Portugal

Center pivot vs surface drip irrigation system results:

- 30% Increased Yield Using Drip

Financial revenue impact (assumption of € 210 / t, with the market pricing at time of the trial)

- Yield Using Drip: 15.6t/ha

- Yield Income Using Drip: €3,276 / ha

- Yield Using Center Pivot: 12.0 t/ha

- Yield Income Using Center Pivot: €2,520 / ha

For a 1600 ha farm, drip irrigation would provide €1.2m extra income

Pivot Long-term Running Costs

Some factors often overlooked when evaluating pivot vs. drip irrigation for corn:

- Center pivots can bog if poor soil quality or high rainfall

- Wheel tracks can be hard to maintain and require regular maintenance

- Pivots with 10+ spans can have double and triple sprinkler packs on the end spans that can cause soil crusting, runoff, poor germination and poor drainage

- Pivots can blow over in mid-high wind which can be expensive to repair

- Copper wire, generators and diesel fuel used on pivots are attractive to thieves

- Gearboxes, universal joints, drive-shafts, tires and electric motors can fail without warning

- Cost of gearbox repairs and flat tire replacements can be expensive

- Unlike pivots, drip irrigation does not irrigate the furrows, therefore fewer weeds and less herbicide spraying required

- Drip irrigation will still work effectively in windy conditions. Sprinkler irrigation will drift causing uneven watering

- Because drip irrigation does not wet the crop foliage, there is less risk of the spread of fungal and bacterial disease

- Foliar spraying operations can occur at the same time as drip irrigation, and no irrigation spray means more insecticide and fungicide stays on the foliage

- Pollination is not affected by lack of overhead irrigation, as pollen stays dry, it has greater longevity and wind-borne pollen is very effective

Rivulis Subsurface Drip Irrigation in Mexico

By using Rivulis subsurface drip irrigation, Agrícola Granos del Valle was able to achieve the following results (over furrow/flood irrigation methods)

- 20% Higher Yields

- 50% Water Savings

- 50% Power Savings

What growers say about their experience using drip irrigation for corn/maize

“We need to switch completely to subsurface drip irrigation urgently… I’m planning to have zero hectares under furrow irrigation in 5 years from now. I want to switch the whole system to subsurface drip irrigation; we won’t install any other pivot. Drip irrigation is very simple and we are saving lots of water.” Jacobo Enns, Agrícola Granos del Valle, Mexico

“Monsanto wants to be at the cutting edge, and drip irrigation is one of the leading technologies because it saves water, a very scarce resource, and also gives higher yields, due to the efficient delivery of water and fertilizers.” Mario Ruiz, Plant Manager of Monsanto’s Villagran plant

Surface Drip System: Typical Design

- One drip lateral every 2 corn rows

- Drip laterals every 1.5 m

- Corn rows at every 0.75 m spacing

- On lighter soil types, it is advantageous to move corn rows closer to the drip line (0.60 – 0.55m spacing)

- Sub-mains are above the surface

- Use 6 – 8 mil wall thickness drip lines

Subsurface Drip System: Typical Design

- One drip lateral every 2 corn rows

- Drip laterals every 1.5 m

- Corn row spacing can be reduced to 30 cm to the side of drip lateral to minimize water use

- Sub-mains are installed below the surface

- Drip tape is installed 20 – 25 cm below the surface

- Use 15 – 30 mil wall thickness drip lines with 30 – 40 cm emitter spacing

- Use media filtration to minimize blockage potential, maximizing longevity of drip lines

- GPS guided tractors critical for bed forming and sowing operations

- Rivulis will match system water output with maximum daily crop requirement

- Careful cultivation required over the top of drip lines

- Can use offset deep rippers either side of the drip line to “renovate” beds with GPS guidance

Please note that case study outcomes are for information purposes only and actual results may vary. This literature has been compiled for worldwide circulation and the descriptions, photos, and information are for general purpose use only. Please consult with an irrigation specialist and technical specifications for proper use of Rivulis products. Because some products are not available in all regions, please contact your local dealer for details. Rivulis reserves the right to change specifications and the design of all products without notice. Every effort has been used to ensure that product information, including data sheets, schematics, manuals and brochures are correct. However information should be verified before making any decisions based on this information.