Proven Irrigation Solutions for Sugar Cane

With increased pressure for profitability, more and more growers are choosing drip irrigation as an effective method for reducing costs and boosting yields. Rivulis has the industry’s most extensive micro irrigation product portfolio and pioneered the development of integrated emitter T-Tape and Ro-Drip and molded emitter drip lines: Eolos and D5000 PC. In addition, Rivulis brings over 50 years of field trusted drip irrigation experience and innovation with expertise in sugar cane irrigation.

High Profit Yields, sugarcane drip irrigation methods

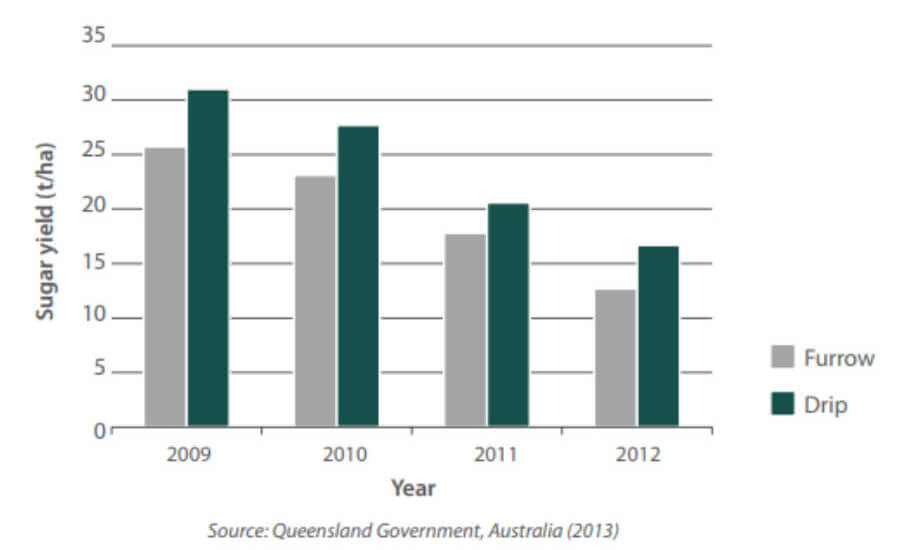

Drip irrigation delivers water and nutrients directly to the cane’s active root zone. With minimal evaporation and leaching, the crop gets the maximum benefit, which in turn means maximum growth. Unlike some crops that can rely on intermittent water applications, cane yield responds positively to high frequency water applications. When a crop is flood-irrigated, a large volume of water is applied, followed by a prolonged dry period before the crop receives water again. This causes stress to the crop which can lead to under-development, especially in sandy soils. Drip irrigation enables pulse irrigation, applying a small volume of water for brief but regular intervals. This provides a better wetting pattern, reduces deep drainage and prevents undue crop stress that reduces yields. In other words, drip irrigation gives your crop the best opportunity to reach its potential yield through high frequency irrigation leading to increased sugar production. Two such examples include: Argentina: Industry stakeholder drip irrigation study site delivered 82% more yield than non-irrigated land. Australia: Even on sandy soil that is not ideal for cane growing, a Rivulis sub-surface T-Tape installation still achieved 172 ton/ha.

Comparison of Sucrose Yield – Furrow vs Drip Irrigation

Promote Growth While Reducing Your Fertilizer Bill

There is only one way fertilizer prices seem to be going, and that’s up! Therefore, reducing fertilizer costs is critical for farm profitability in the future. Drip fertigation allows for the injection of fertilizer through the irrigation system, directly to the plant’s active root zone. Not only does this method of fertigation significantly reduce leaching, it also enables the application of small doses of fertilizer in regular intervals, which promotes growth.

Spray Less and Save Fuel

Weeds in a sugar cane field can require multiple spray passes to manage. Not only does this cost in terms of labor, fuel and spray, every tractor pass compacts the ground, damaging the plant’s root zone. Because subsurface drip irrigation applies water below the surface, the furrows do not get wet from irrigation. Without water, weeds cannot germinate and grow, often eliminating the need to spray for weeds altogether. Drip irrigation can also reduce the risk and subsequent potential loss caused by smut infection when compared to furrow and overhead irrigation.

Sugar Cane Project in Peru

Delivers Outstanding Results Rivulis delivered a 2700 ha turnkey drip irrigation for sugar cane project using Rivulis D5000 PC Drip Line and Rivulis Media Filtration systems. Rivulis provided design, technical, logistic and agronomic support to deliver an integrated irrigation system that incorporated automation and fertigation.

Save on Labor

Labor costs and availability are increasing challenges for growers globally. Drip irrigation methods reduces labor input requirements. You can turn on your drip irrigation system by simply turning on your pump, or if you use automation, you can start the system remotely. Applying fertilizer is also easier with drip and it is as simple as filling a tank in the pump shed with fertilizer and pushing a button.

Reduce Water and Pumping Costs

Everyone knows that drip irrigation saves water. However, when it comes to saving water, every mega-liter you don’t use is also a mega-liter you do not need to pump. This can lead to significant savings in energy costs.

Drip Irrigation Systems & Rivulis Solutions

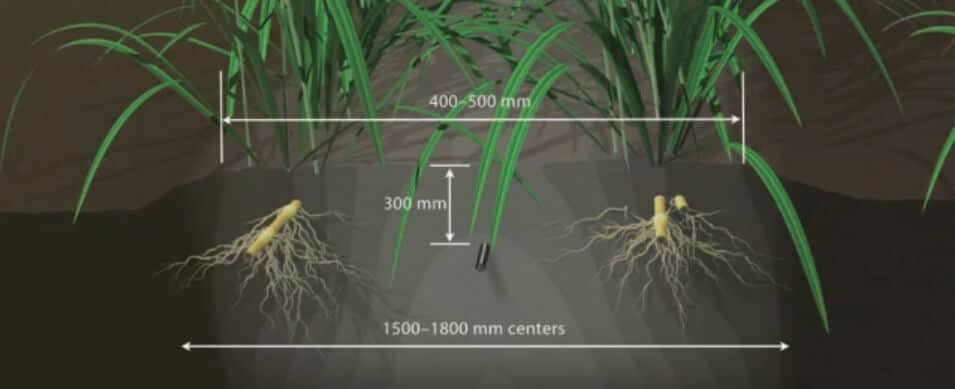

A list of the major components of a drip irrigation system is listed below. Rivulis has the range and expertise to deliver your next project. “We use 5.5 mega-liters per hectare. The local average for flood is 12.5 per hectare.” Pump shed Pump: Pressurizes the system. A variable speed electric pump will provide maximum efficiency. Primary filtration: Prevents particles entering the irrigation system. A Rivulis media filter will provide optimum protection. Fertigation system: Injects specified fertilizer doses directly into the irrigation system. Automation system: Controls and monitors the irrigation system including valves, fertigation and pump operation. In-field Main and sub-lines: Buried PVC pipe that transports water throughout the farm. Secondary filtration: Back-up smaller filters. Rivulis F6000/F7000 plastic filter range is ideal for this application. Valves: Control water flow and regulate pressure. Use Rivulis V2000/V2500 plastic and V3000/V3500 metal valves. Drip Line: T-Tape / Ro-Drip / D1000 / D2000 /D5000 / Eolos / Eolos Compact drip line laterals that run the length of the sugar cane rows and emit specified flow per dripper. Automation: Remotely controls and monitors your valves and pumps.

Typical Installation: Subsurface Drip Irrigation (SDI)

Complete Turnkey Solutions

Balancing between your unique needs, Rivulis provides the right solution with a full range of expertise to deliver complete turnkey projects across customers and geographies.