Onion is one of the oldest plant species to be domesticated and cultivated

Onion (Allium cepa L.) has been grown and selectively bred in cultivation for at least 7,000 years. Onion is assumed to originate from Central and West Asia. Traces of onions recovered from Bronze Age settlements in China suggest that onions were used as far back as 5000 BC. Today, onion is grown all over the world and is a common ingredient in many cuisines.

Source: FAO, 2012

With world production of 74,250,809 tons from an area of 4,364,000 hectares, onion productivity is highest in the Republic of Korea (66.16 t/ha), followed by the USA (56.26 t/ha), Spain (53.31 t/ha), and the Netherlands (51.64 t/ha). The latest, being the highest onion exporter (1.33 million tons).

Seeding – Sowing the seeds with a steady hand

The seeds of the Allium family are relatively small compared to other crops. This has an impact on the sowing methods. Since the seed is small, it can’t be sown too deep in the soil, because it lacks the reserves to sustain itself for long during germination.

On the other hand, it cannot be sown to close to the surface for risk of drying out. Even after sprouting, the Allium sprouts are so small and delicate, some forms of irrigation (like a water gun for example) can harm the young plantlet. Therefore, there are very specific instructions regarding the seeding process of onion. Depending on the variety and type of soil, the seeds will be sown at a specific depth (1/4 – 1/2 cm), and the preparation of the seed bed must be implemented accordingly.

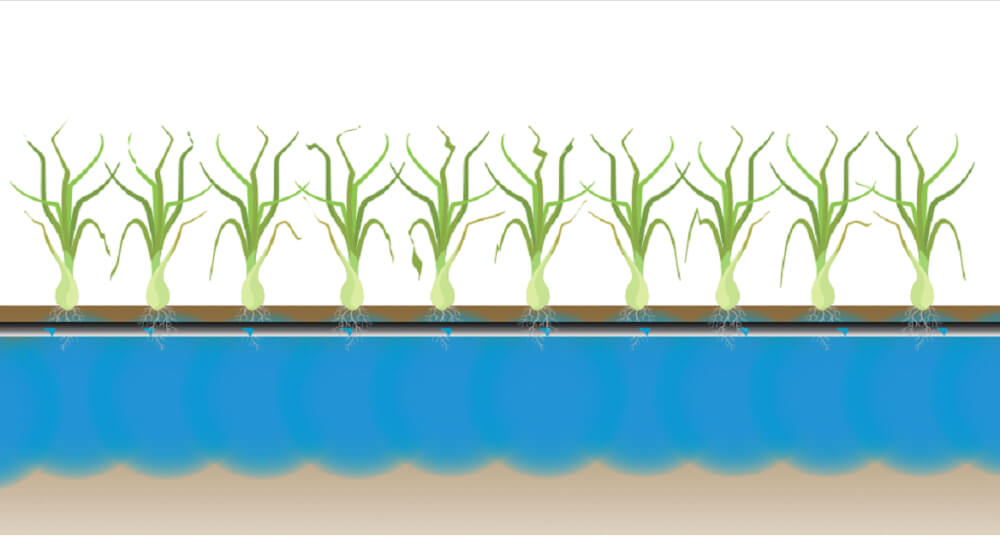

Instant water supply

Sometimes, during the germination stage, due to the shallow depth of the seeds, the grower must irrigate, sometimes as often as three times a day. Once the germination process is in motion, the grower has to be able to control the soil moisture levels in the seed bed. The optimum solution to achieve this is to install Rivulis drip tape/ drip line at the same time as sowing. This ensures a perfect response time and the ability to irrigate instantly.

Sowing and laying out the laterals simultaneously ensures not only the perfect timing proximity but also the perfect spatial proximity, making sure the drippers are right where they should be in relation to the seeds.

Advantages of drip irrigation for onions

Onions have a relatively small and shallow root system. This means that the relevant area to be irrigated and fertilized is quite narrow and close to the plant itself. Actually, most of the field is irrelevant when it comes to inputs like water and nutrients. This is what makes drip irrigation ideal for onion cultivation. When using drip irrigation for onion, only the row itself is irrigated saving on water and fertilizers. In the beginning of the season, especially, there is very limited water consumption by the plants and irrigating the whole field with overhead sprinklers for example, or pivot is unnecessary.

Water logging prevention

Areas subjected to rain events during the irrigation season might experience flooding and water logging from time to time. Targeting the relevant root zone solely and leaving the rest of the field dry enables improved infiltration and water holding capacity.

Mycorrhiza and plant working together

Microfauna in the soil plays an important role for plants in general and for onion in particular. Mycorrhiza and other bacteria improve nutrient uptake by the plant and increase many growth factors. Ensuring beneficial environmental conditions in the soil, such as improved water/air ratio induce mycorrhizal activity and consequently improve plant growth and yields.

Location, location, location – lateral location and drip spacing

Locating the lateral just a few centimeters under the soil surface has an immense advantage. Supplying water and nutrients in the immediate vicinity of the young roots allows the grower to save huge amounts of water and fertilizers compared to other means of irrigation. Overhead irrigation, for example will wet the whole field regardless of the location of the seeds or the plants. Using a drip irrigation system with laterals slightly submerged and drip spacing of 20 cm gives the grower an unprecedented ability to supply water and nutrients directly to the root zone of the newly germinated onion plant. Naturally, locating the lateral a few centimeters under the soil surface leaves the field clear of any components enabling the smooth applications such as spraying and weeding.

Ultra-low flow (ULF) drip irrigation – water by demand

Flow rate – the volume of water which passes through the dripper a given unit of time. There are many different types of drippers with various flow rates. Some drippers emit 8 liters of water per hour and some low flow rate drippers emit 1 liter of water per hour. Only in recent years, companies like Rivulis, have launched Ultra Low Flow Rate drippers. These new and revolutionary drippers can emit very small volumes of water with flow rates as low as 0.25 liter per hour. The use of Ultra Low Flow drippers enables longer irrigation durations, agronomic benefits (see below), while minimizing leaching of valuable water and fertilizers.

ULF: Redefining Micro Irrigation

Rawlins and Raats (1975) found that a continuous high level of moisture in the root zone enables higher hydraulic conductivity leading to higher water availability in the plant. Having a dripper which emits water practically at the same rate in which the root intakes the water is an incredible achievement! This way we can actually optimize the moisture and nutrient levels that the root is exposed to.

ULF: Avoiding Anoxia

Applying a large volume of water through a high flow rate dripper means creating a local micro environment which lacks oxygen (Anoxia). Just under the dripper and around it, depending on soil type and flow rate, there are temporary conditions of anoxia. In this stage, all respiration activity is inhibited. Roots and bacteria alike experience a sort of suffocation. One of the great advantages of Ultra Low Flow drippers is that it avoids anoxia. The rate in which water penetrates the soil allows a much better air to water ratio which, in turn, slows biological respiration activity. In practice, some pathogens benefit from Anaerobic conditions as found in highly saturated environments which are more common in higher flow rate drippers. In these conditions, disease risk is increased.

ULF: Nutrient uptake

Extractable P concentrations in the soil immediately surrounding the point source were found to be 20 to 25% higher in continuously irrigated soil as compared with pulse irrigation. After 40 days of growth, corn plants grown under continuous fertigation yielded 20% greater biomass than plants irrigated with the same water quantity and quality once every 2 days. Phosphorus content of corn leaves was 25% greater for the continuous treatment as compared with the pulse treatment. Ben-Gal, A. and Dudley, L. 2003. Phosphorus availability under continuous point-source irrigation. Soil Sci Soc Am J. 67:1449-1456

Initial investment and infrastructure with less cost

One of the major advantages of low flow rate drip irrigation is economics. The lower the system flow rate the smaller the diameter of the main and submain can be. That alone can reduce the cost of the irrigation system substantially. The pumps and filters can all work on a smaller scale which saves a lot of money. In fact, the whole infrastructure is reduced in size making the initial investment much more economic to the farmer. Lower flow rate drip irrigation saves energy, water, time and money! It is simply much more efficient to the user.

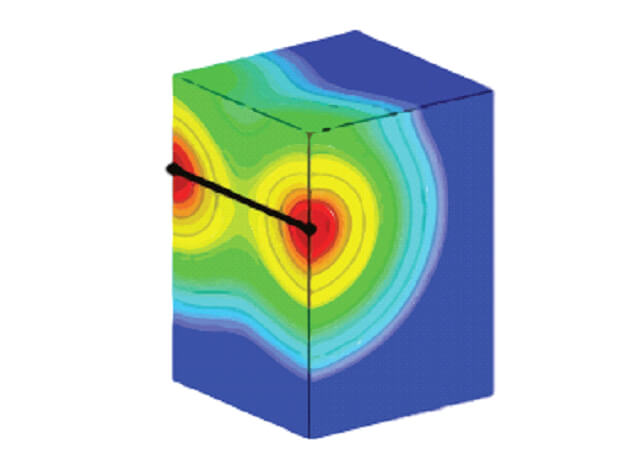

SDI – the advantages of a slightly submerged irrigation system

The water distribution in the soil is determined by several different factors. However, any way you look at it, subsurface drip irrigation (SDI) sets you off to a good start. Most of Rivulis’ drip irrigation products that are suitable for onion can be installed below soil surface. SDI in this case is not deep burial, but shallow burial. In onions this improves lateral water movement and nutrient distribution in the root zone. It improves the above ground moisture conditions creating a better micro climate for the plant. These conditions can benefit most crops but when it comes to onions, a dry soil surface improves skin quality and appearance, and most importantly, reduces disease risk (pressure here does not make sense).

Shallow burial drip irrigation

An installation a few centimeters under the surface improves water movement and air-soil-water balance as water distributes in a sphere of 360 degrees when exiting the dripper rather than a 180 degrees when the dripper is on the surface.

Soil Water Content Using Subsurface Drip Irrigation.

Using subsurface drip irrigation, water movement is 360° between each drip emitter as shown in the above illustration.

15-20 cm is often the ideal dripper spacing for onions. However, spacing will depend on soil type and other factors. However, in general for onions, you want close spacing to ensure uniform water distribution. The closer, the better.

Tapes & thin wall drip lines – single season use solution for onion

When it comes to onions, crop rotation is a must! Usually, onions should not be cultivated again within 5 years on the same plot. This allows the soil to rejuvenate itself, thus, not allowing the establishment of Allium specific pathogens. Once the season is over, the specific irrigation system used is no longer relevant. Often, the crops that follow onions in the rotation are different kinds of cereals which are rain fed by nature and do not require irrigation. In these applications, the best solution is seasonal tapes and thin wall drip lines that are used for each season only.

THE WIDEST RANGE OF DRIP TAPES AND LINES

Don’t compromise on what you really need. No other irrigation provider offers the range of drip solutions that Rivulis does.

T-TAPE

The best strength, the best water application, the best configurations, and the best clogging resistance by far.

RO-DRIP

Incredible 5 star performance under difficult conditions. Unique vortex flow path which expands with increased pressure for easy cleaning.

D900

Top performance thin wall drip line that maximizes run lengths.

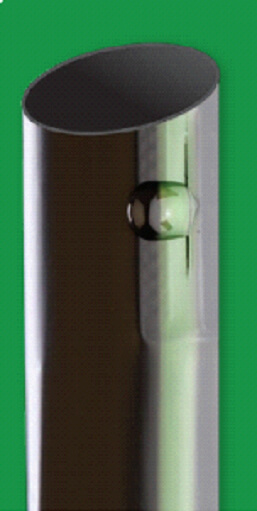

D1000

The world’s first thin wall molded emitter with ActiveFlex™, and a slit outlet to prevent soil ingestion at shut-off.