Electric or Diesel irrigation pumps – what should I choose?

One of the most important decisions which farmers make when implementing an irrigation system is to choose the correct pump type. Here are some pointers on what to look for when making this decision.

The pumping unit dictates both the efficiency and savings. Here are some tips on how to choose the right pump.

By Romeo Dragan Product Manager Rivulis

For decades, the standard in pumps used for irrigation was diesel combustion engine portable pumps, and for good reason. Their ability to be set-up even in the most remote areas where electricity networks were limited made it the obvious choice. Electricity availability is not the only selection criteria as the electric network can always be extended to reach the field to be irrigated, but not without a cost. Most of the times, the cost to extend the electric network is considerable so only by taking this cost into consideration we can reach a fair conclusion on what is best for your irrigation project.

If both electric and diesel options are on the table, we then need to dive deeper and take a look at the operating cost of each of the options. By calculating the operating costs over the estimated hours of operation we plan for our irrigation system, we can then determine which pump is most relevant.

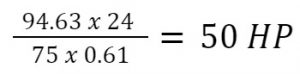

Let’s take an example of an irrigation system using 340 m3/h and 2.4 bar (1500 GPM and 80 feet of head) and a 0.61 efficiency factor which is common for pumps used for irrigation.

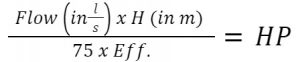

Step 1: Calculating the power required at the engine/motor:

-

- Formula for US measurements: Flow (in GPM) x Head (in ft.) ÷ Eff. ÷ 3960 = HP

1500 x 80 ÷ 0.61 ÷ 3960 = 50 HP

Step 2: Calculating likely operating cost:

- For diesel engine:

Metric: 50 HP x 5.28 (conversion factor to l/h) = 9.5 l/h of fuel = hourly operating rate of $7.5

US measurements: 50 HP x 0.05 (conversion factor to gph) = 2.5 gph of fuel x $3 (cost of 1 gallon of fuel) = hourly operating rate of $7.5 - For electric motor:

US measurements: 50 HP x 0.746 (conversion factor to kWh) = 37.3 kWh x $0.1 (average cost of kWh) = hourly operating rate of $3.73

Step 3: Calculating the operating costs over time:

Here we need to consider the following aspects in order to have a better view: 1- number of hours the system will operate and 2- the other costs involved like the cost of expanding the electricity network

System working hours: Pump operates each season for 12 hours/day and 80 days on average

Electric network expansion: $5000

Diesel calculation: $7.5 /hr. x 12 hrs. x 80 days = $7200 /season

Electric calculations: $3.73 /hr. x 12 hours x 80 days = $3580 /season + $5000 for the 1st season

|

Season 1 |

Season 2 |

Season 3 |

Season 4 |

Season 5 |

|

|

Diesel costs |

$7,200 |

$14,400 |

$21,600 |

$28,800 |

$36,000 |

|

Electric costs |

$8,580 |

$12,160 |

$15,740 |

$19,320 |

$22,900 |

1st season shows higher operating costs for the electric option but have a look at what happens in the coming seasons.

Conclusion

Investing in an irrigation system is a long-term investment and only by studying what happens in the long run we can truly see what the investment will yield. The above example is only to prove a point but each farm is different and therefore the number swill be different for every farm. Some regions of the world subsidize diesel or electric pumps and in this way the calculations might tell a different story– we just need to see what works best for you.

Disclaimer: The above is provided as general advice only. Every application is different, and the maintenance regime you require for your pumping unit should be developed in consultation with the user manual delivered by the pump producer.