Filtration protects your irrigation system, but how do you protect the filtration unit?

The main system head is the “heart” of the drip irrigation system. It enables the emitters to work as designed and that the water is being distributed as per the irrigation design. Keeping the filter running to the designed parameters is the least we can do in order to provide our plants with the necessary nutrients.

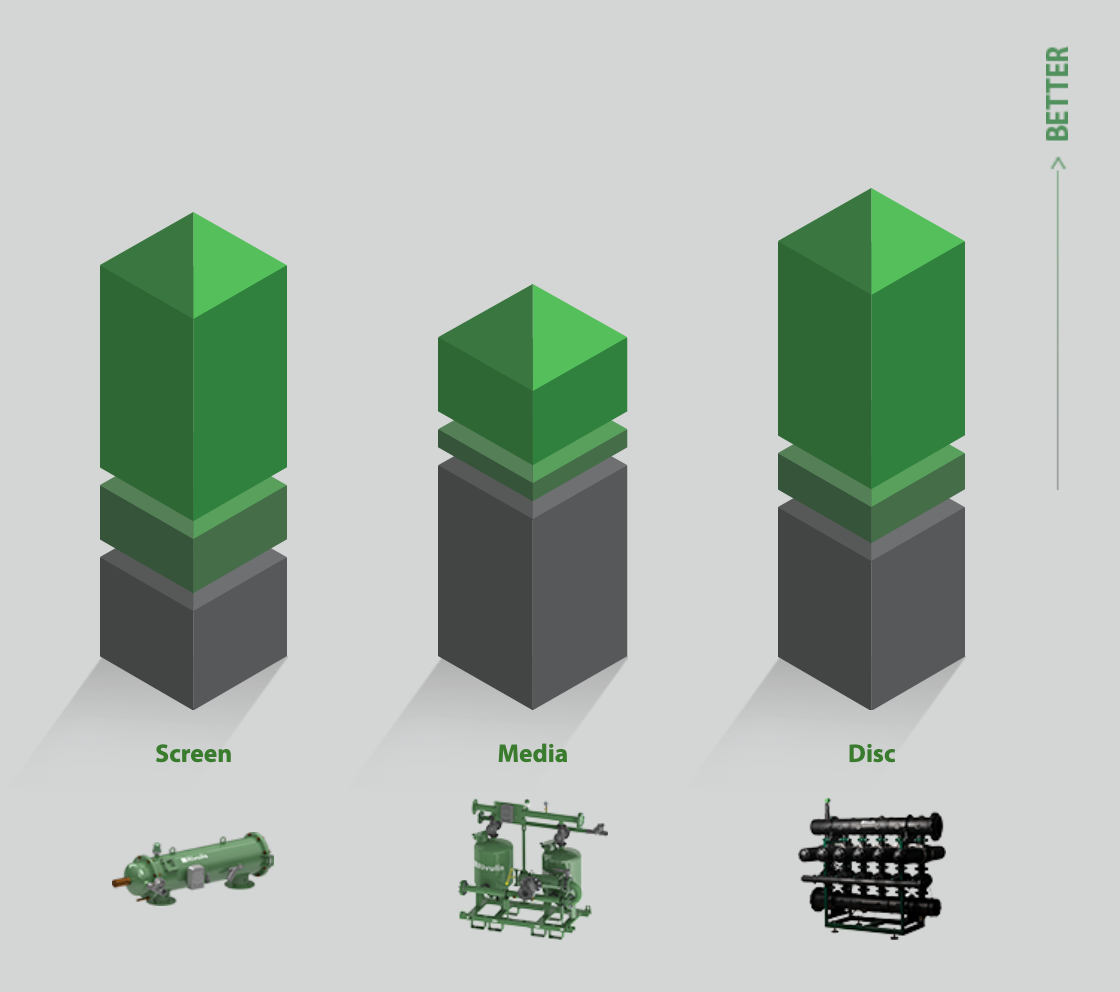

There are different types of filters available such as screen, disc or media filters. Each of these filters have different recommendations for check-ups which we will review below.

By Romeo Dragan Product Manager Rivulis

First, we need to inspect for leakages and fix them. For metal filters, look for any damage of the coating and repair it to maintain the integrity of the housing intact.

Making sure the filter is able to backflush and clean itself is something we need to check at least once a month. The filter’s performance is dependent on its ability to flush and clean properly. Any accumulations of dirt caused by improper flushing will eventually clog and damage the filter. Filter flushing can be manual, semi-automatic or automatic and this refers to the trigger that causes the flushing to take place. Manual and semi-automatic filters are flushed manually by the user. Semi-auto can have a clogging indicator to show when the filter needs cleaning. Automatic filter flushing is triggered by an irrigation controller measuring the pressure differential across the filter and also performs the flushing at set time intervals.

Warning, before opening the filter, close the water supply and drain the filter. Read the operating manual and look for special service needed like lubrication of rubber parts and grease on the metal threads.

Pressure differential

Monitoring the pressure differential between the inlet and outlet of a filter will provide us information regarding when the filter is starting to be clogged and needs to be flushed. We need to make sure that the filter is flushing properly and to check this, we can initiate a manual flushing sequence and check that the pressure differential drops to the designed pressure differential after the flushing is completed.

Checking the pressure differential and comparing it to the standard value according to the filter technical documentation will tell us if the flushing is working as it should. Usually a pressure differential below 0.25 bar (4 psi) is considered normal head loss.

- If the pressure differential is above the normal pressure differential – this means that the screen, disc or media is clogged. If this happens, most likely we will need to consult the user manual, open the filter and inspect for damage.

- If the pressure differential is lower than the normal pressure differential – this means that the filtration medium is not filtering correctly and water is passing through unfiltered. It might mean a broken screen or that the discs are not being pressed together or in the case of media filters, it might mean that tunnels have been formed in the media and water passing though the filter without being cleaned.

Automatic flushing

Special attention needs to be paid to automatic filters because here the flushing operation relies on the irrigation controller and other electric and hydraulic components for it to be performed. The filter back flush controller will be able to display detailed information on the filter flushing frequency and the reason for flushing.

If we notice the flushing frequency is too high, this might indicate that the filter remains clogged after flushing or that the set pressure differential value is incorrectly set on the controller. Faults in automation and sensors can also be considered here.

If the flushing frequency is too low this might be a sign of mechanical failure or faults in automation and sensors. It might also mean that the filtration medium (screen, disc or media) has been breached and water is not being filtered properly.

Maintenance recommendation

Open the disc filter housing and release the piston holding the discs pressed together. Take the discs out and apply water with pressure until the disc grooves are cleaned. Visually inspect and replace any damaged disc.

If needed, soak the discs in a chemical solution intended to clean any organic and biological residue. The user manual should indicate which chemical to use. Make sure to flush the filter a few times to remove all chemicals before resuming normal operation.

Take the screen out of the housing and visually inspect it to make sure it doesn’t have any cracks or damage. If needed clean the screen manually using pressurized water.

The suction nozzles should also be checked to ensure they are situated at the correct proximity to the screen, which ensures that they can clean the screen properly.

Special attention needs to be paid to media quality and quantity. The filter might lose media during flushing so it may require additional media to be added from time to time. The quality of the media needs to be examined by touch. The media grains should be loose and have sharp edges – this is a sign that the quality of the media is still good. If the media drains start to have rounded smooth edges like beach sand, this is a sign that it is no longer providing quality filtration and should be replaced.

The blunting of the media might take a couple of years before it takes place depending on the water quality and irrigation frequency, but it will eventually happen so best to notice it before it does.

Other components on the main head

All automatic cleaning filters regardless of their type have one thing in common: the hydraulic and electric components used for opening the flushing valves for cleaning. Be sure to clean the small plastic filter and micro-tubing operating in this hydraulic circuit. The irrigation controller will let you know if the batteries need replacing so check the controller screen when possible.

Conclusion

Constant flushing issues might also be a sign that we are using the wrong kind of filter.

Choosing the right filter is critical. There are tools out there which can help farmers make sure they are using the right kind of filter for any specific water source. When choosing the filter, it’s not just about choosing the technical specifications but also an experienced supplier – this will save you a lot of trouble down the road. At Rivulis, we have a great tool to provide a filter recommendation for your farm – https://rivulisdev.co.il/filter-calculator/.

Disclaimer: The above is provided as general advice only. Every application is different, and the maintenance regime you require for your drip irrigation system should be developed in consultation with an irrigation professional or your Rivulis representative.