Soilless Commercial Blueberry Farming: Techniques and Innovations

Introduction

Rivulis has supported many blueberry farmers with their irrigation needs and knows that blueberries can be challenging to grow. Remarkably, there are around 150 varieties of blueberries, and they can be categorized into four main groups. The Northern highbush varieties grow best in the northern US and Canada, the Southern highbush varieties do best in moderate climates, Rabbiteye blueberries are best suited to the Southeast and Southern Hemisphere, and Lowbush are typically wild varieties.

Most commercialized blueberries belong to the highbush species, and many varieties are crossbreeds between the Northern and Southern species. Blueberries require very specific climate characteristics and mainly favor a cool climate. Growing blueberries in arid zones can be very difficult and require special attention to create optimal conditions. Current commercial blueberry farming practice is that the plants are typically grown in containers under net houses or in tunnels. Blueberries are highly sensitive to lack of oxygen and growing them in a well-aerated substrate can support adequate oxygen levels.

Crop Needs

Climate:

Blueberries are highly vulnerable to changing environmental conditions and require precise chilling hours in the winter to ensure blooming and leaf development as well as optimal fruiting. For this to happen they need a certain amount of time exposed to cold temperatures.

Defined as “chilling”, this is the accumulated number of hours needed for flower buds to develop on a dormant blueberry bush in the winter. Depending on the variety, chill temperatures are defined as less than 7 degrees Celsius (44 Fahrenheit) but above 0 degrees Celsius (32 Fahrenheit). Without sufficient chill hours, berry yield output will be reduced; Southern highbush cultivars tend to need fewer chill hours than Northern highbush cultivars.

Blueberries are sensitive to high temperatures, particularly during fruit ripening. If the crop is exposed to heat waves this is likely to reduce fruit quality and present appearance issues like spotting, shriveling, poor coloration, and fruit softening. Temperatures that are too high can reduce carbohydrate assimilation, trigger oxidative stress, and diminish blueberry fruit quality and shelf life. When growing blueberries in hot climates where temperatures can reach over 32-35oC (90-95 Fahrenheit) foggers are necessary to cool plant surroundings to prevent heat damage.

Selecting the right cultivar for the region is imperative to the success of the farming operation. Some cultivars are more sensitive than others to heat, salinity, and cooling requirements.

Growing Conditions:

Usually grown per bush in large containers of approximately 40 – 50 liters (10.5 – 13.2 gallons) in size, 6000 to 8000 plants are typical in a 1-hectare (2.47 acre) block. These are arranged in 2 – 3-meter (6.5-10 feet) row spacing, with there being 0.5 – 0.8 meters (1.6-2.6 feet) between each plant. Irrigation is calculated according to the growing area (that is the number of plants per block), and the substrate used to grow the plants can vary from coco coir to peat, perlite of a mix of different substrates.

It is very important that the substrate is well drained and has adequate air-to-substrate-to-water ratios to ensure the plant has sufficient oxygen (to prevent anoxic conditions from occurring).

Rhizosphere pH:

Blueberries have evolved to grow in acidic soils, with the ideal pH being between 4 – 5, although if the organic matter in the substrate is high enough, they can stretch to between 3.8 – 5.5. This can be achieved in the rhizosphere (the region of the soil in the vicinity of the plant roots in which chemistry and microbiology are influenced) by acidification of the root zone using acid of nitrogenous fertilizers. Nitrogenous fertilizers contain ammonium (like ammonium nitrate, MAP, and AMS) that will reduce the pH of the rhizosphere.

If high-pH water is a problem, continuous injections of acid into the water are recommended to maintain the pH at acceptable levels.

Salinity:

Blueberry plants are extremely sensitive to salt and berries salinity stress. High salt levels in the substrate and or the water will reduce the plant’s water uptake, reduce yield, and fruit quality.

Conductivity is a measure of water’s ability to conduct an electric current. Because dissolved salts and other inorganic materials conduct electrical current, conductivity increases as salinity increases.

For berries, an electrical conductivity (EC) of 1.5 (dS/m) is considered high. Prolonged exposure to this level of salinity will affect plant growth and decrease yields. Irrigation water for blueberries should have an EC of less than 1.5 (dS/m) chloride, and sodium of less than 100 ppm, and boron of less than 1 ppm. If salinity build-up is a potential problem, irrigation should be scheduled in smaller, more frequent applications.

Irrigation water must be analyzed to ensure adequate growth conditions.

| Test | Fine | Be careful | Problem |

| Electrical conductivity (salinity) |

0.8 dS/m | 0.92.3 dS/m | >2.3 dS/m |

| pH | 5.5-6.5 | 6.6-8.5 | >8.5 |

| Chloride | 0.04 oz/gl | 0.04-0.05 oz/gl | 0.05 oz/gl |

| Iron | – | Change 0.1-1 ppm | Change 1 ppm |

Irrigation requirements

The average daily water requirements depend on the variety of the plant, its size, and growth stage. Most commercially grown blueberries are of the Highbush variety and proper irrigation management is critical to yield and quality. Water stress develops quickly in blueberries, and this reduces the plant’s ability to photosynthesize, leading to lower growth rates and fruit production.

A lack of sufficient water volume will cause damage to the growth of the plant, and it is very difficult to correct at a later stage. Water limitations during later stages of fruit development will decrease yield, berry size, and fruit bud set. In contrast, over-irrigation decreases blueberry root function and increases nutrient leaching. This makes it more likely for the plant to develop crown and root rot infection by pathogens.

Irrigation Demand:

Depending on the surrounding climate, a mature, lone blueberry bush can use up to 8 – 10 liters (2.1 – 2.6 gallons) of water per day (drainage included).

In most cases, blueberry irrigation systems should be designed to provide a peak demand of 10 liters (2.6 gallons) per plant per day. The flow rate should be high (around 5-7 liters per hour (1.3 – 1.8 gallons), with no drain feature so that pulse irrigation methods can be applied.

The drip-emitter configuration must ensure that salts in the water are moved from the center of the container towards the side and bottom so that the main roots have optimal salinity rates. 20 – 30% drainage is ideal.

Depending on their size, younger plants need less water. A 1-1.5-meter (3.2 – 4.9 feet) plant has a peak demand of about 3 liters (0.8 gallons) of water per day and new plantings around 1-2 liters (0.2 – 0.5 gallons) per day. The newly planted bush has a very small root volume, and the plants are very susceptible to water stress.

Water dispersity must be very accurate: water uptake is much faster than minerals, which means salinity can increase rapidly if it is not managed correctly. To prevent salt build-up in the plant containers from fertilizers it must be ensured that the emitter flow rate and the number of emitters per container are optimal for adequate drainage.

Irrigation Timing and Frequency:

Water consumption needs depend on the plant’s physiological activity and can change according to crop growth stage, radiation, and temperature.

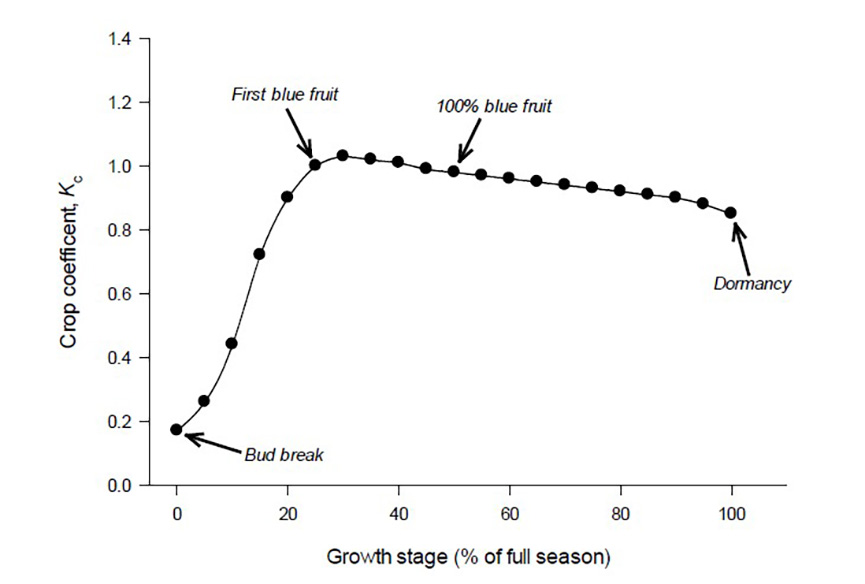

Crop coefficient curve for Highbush blueberry (obtained from AgriMet). (Source: D. Byrla., USDA)

The best way to monitor and control the plant’s water consumption and supply is by weighing the container or using sensors in the substrate and greenhouse. Doing this gives a direct indication of water consumption along the plant’s growth trajectory and enables an efficient irrigation and fertigation regime. Frequent water applications are especially important when using drip irrigation – if properly done this is likely to raise yield in most crops.

Crop Nutrition

Nutrition recommendation for soilless-grown blueberries

nutrient concentration (ppm)

|

growth stage |

N |

P2O5 |

K2O |

CaO |

MgO |

SO4 |

|

Vegetative |

100 |

50 |

100 |

100 |

65 |

80 |

|

Flowering-Harvest |

80 |

50 |

150 |

100 |

65 |

80 |

Every drop of water will contain the same concentration of nutrients as well as high quality fully water-soluble fertilizers. Fertilizers used should not contain chlorine or sodium which can cause salinity issues and damage plant development.

Irrigation System Design

Rivulis has a range of suitable micro-irrigation solutions that suit blueberry cutting-edge blueberry farming techniques.

Drippers

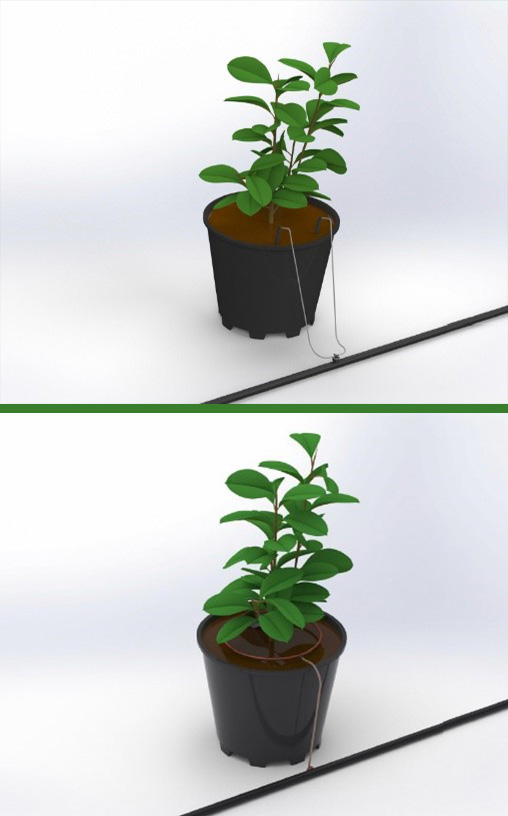

Online drippers have the advantage of being customizable to many configurations, they have unique PC/AS technology that allows for accurate pulse irrigation.

An example of a possible dripper configuration:

Rivulis Supertif with 2 pegs (depending on pot volume) enables an even spread of irrigation water to the plant root zone.

Using the Rivulis Supertif with the Rivulis Hydro Bloom ring (which can be supplied according to the pot size) supplies even more accurate irrigation water and reduces installation labor.

Automation and Fertigation

Rivulis has a wide range of controllers and fertigation machines, and the right solution depends on cropping needs.

Depending on flow rates and the number of channels needed for fertilizers and other necessities, the C8300 and C9300 fertigation machines combined with the C4300 controllers are ideal for fertigation.

For climate control, the C4100 climate controller is the recommended solution to control humidity and cooling or any other climate control system components.

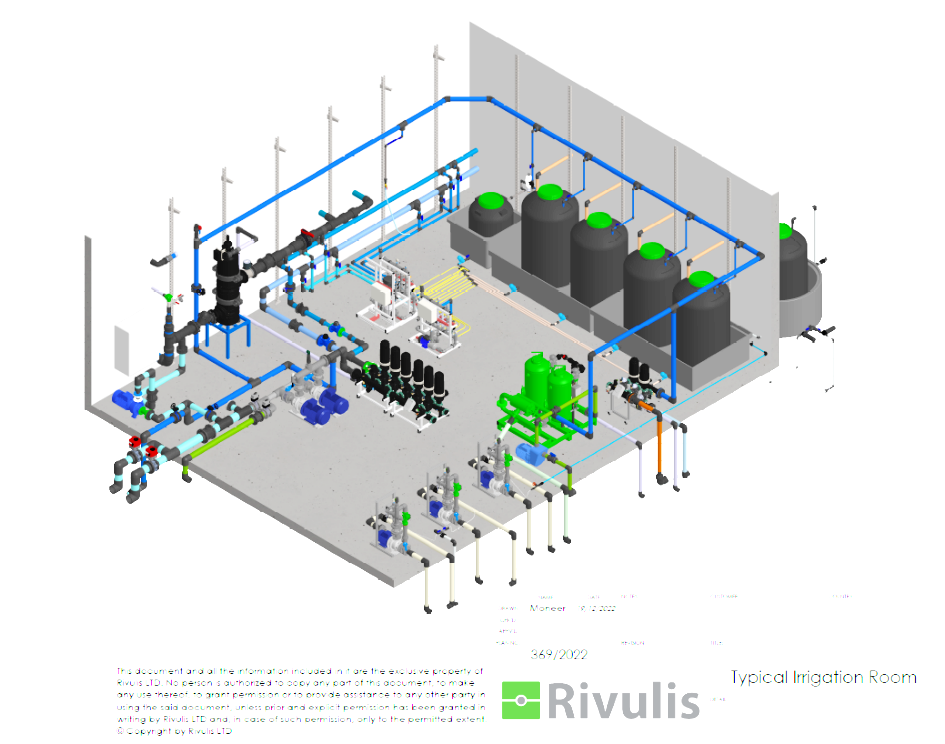

Irrigation Room:

Many components are required for the irrigation system of a blueberry project. The design of the irrigation room from its structure to each of the irrigation system components needs to be done to create maximum efficiency for the growing process and the operation.

Choosing the right pumps, filtration systems, fertigation machines, and fertilizer tanks is crucial.

Designing the irrigation room should happen upfront at the start of the project. Through Rivulis’ expertise, it has supported many growers in this.

Cooling System

A cooling system is essential, especially if the farm is in a hot climate, and fogging is the most energy-efficient way to cool plants in protected environments. The Rivulis Super Fogger is an optimal and economical solution for cooling, humidifying, fungicide, and pesticide spraying in greenhouses.

This system maintains low temperatures without droplets reaching plants. Versatile options include single, two, or four outlets with built-in leakage prevention devices for economic efficiency.

Operate at 4.0 bar for high pressure or 3.0 bar for medium pressure, ensuring minimal foliage wetting. Easy installation, low maintenance, and chemical-resistant materials guarantee reliability.

The cooling system must operate in a way that no droplets should evaporate and not reach the plant.

Conclusion

Rivulis is proud to have many successful blueberry farmers as customers from all around the globe. Our extensive expertise, agronomists, engineers, and designers have helped farmers establish profitable blueberry operations. Our heartland is our growers, and we are here to help them prosper.